Evolution of steel responsible in the transformation of the Industrial economy

INDUSTRIAL ECONOMY

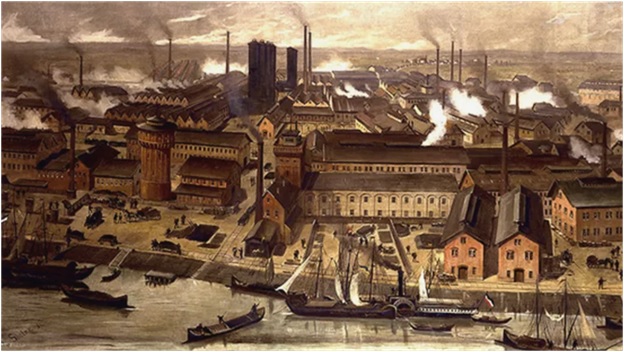

In the British economy, one of the basic requirements was Iron for rapid industrialization. From 1700 – 1750, the iron industry was not so efficient that’s why most irons was imported into Britain. At that point of time over half of the iron used came from Sweden. Since the British industry was engaged in war, when the costs of imports rose and became problematic.

As the industrial revolution developed, the iron industry was also on the boat and explored. Innovations from different materials along with new techniques, iron & TMT production expand greatly. 1825 is known as the start of the new Iron Age. At this time the iron industry experienced massive growth. The demand for railways, bridges, tunnels and more heightened. Meanwhile, the demand increased from civilians, they started using iron in many household structures and even window frames. Britain became well known for railway iron.

In architecture before 1800, metals played a supporting role. At that period masonry was used for bonding, chains, and steel rods were used for roofing, doors, windows, and decoration. The first metal, Cast iron substituted for traditional structural materials, and was used in bridge building in 1779. Architectural adaptations encouraged due to its ability to bear loads, its resistance to fire and corrosion and an endless variety of forms. With the cast iron, first they started columns and arches and afterward in skeletal structures. Cast iron works better as a small column than as a beam since it is much more compressive than tensile strength.

By the mid-eighteenth century, the iron industry was on a downward trajectory. Iron workers needed charcoal to smelt the iron ore. But charcoal was in short supply since the wood required to make charcoal was too expensive. This faced an industrial problem. Now what was required is a method by which iron could be smelted in high tonnage quantities. Which needed a better heat source than charcoal, mostly a new fuel for treating iron ores.

The fuel they found was coal. In the due course, a substantial change occurred as the fuel for the smelting process coal replaced charcoal. Coke proved to be a far superior material for converting iron ore to iron and then to steel. It was obtained by heating coal in the absence of air. The materials were low-cost and abundant in supply. This revolutionized the metal industry and the use of iron and steel.

The conversion of the iron and steel from charcoal to coke was established. The high concentration of sulphur in coal and other impurities makes iron brittle. Steel was much stronger and less brittle than iron. But steel was more difficult to make. This drawback encouraged more new inventions.

The key discovery was that the amount of carbon present in the iron is responsible for its brittleness. Carbon not only controls its melting point but also its properties. By controlling the additions of carbon, a form of iron was made called steel…

Along the way, it was discovered that the amount of carbon present in the iron not only controlled its melting point but also its properties. The addition of carbon is being controlled through the use of coke. This form of iron was called steel which could be cast on an industrial scale.

In the late 19th century iron was largely replaced by the best TMT. Due to its high resistance to all stresses, TMT steel was considered more uniformly Flexi, strong, elastic, and workable.

The steel structure is rolled in a variety of shapes. Most are plates, angles, I beams, and U-shaped channels. These shapes may be joined by steel bolts or rivets. In the 20th century, the development of welding made it possible to produce fused joints with far less labour and materials. The results of these innovations are rigid and strong. That is a fundamental change in architectural technique, the effect of which cannot yet be estimated.

REVOLUTION: STEEL

Sir Henry Bessemer, an English inventor, conducted a series of classic experiments on the steel-making process. For almost one hundred years from 1856 to 1950 his technique was the most important and only technique for making steel. As per his technique, he used various designs of furnaces for burning off the carbon in the iron. At one point in his work, he noticed, that when trying to make steel, he didn’t need to heat or supply fuel to the charge of molten iron. The 4% carbon present in the cast iron would burn, and produce heat. It blows the air through the molten metal after it is removed from the furnace. In this process, being the metal hot and fluid and reduces the carbon content as well. This is the key invention of Bessemer’s process.

For the mass production of steel from molten pig iron, the Bessemer process was the first inexpensive industrial process before the development of the open hearth furnace. The key principle is to remove the impurities from the iron.

These advancements made the iron and steel industry flourish. People, especially farmers, demanded the regulation of the railroads. by the railroad companies, they were constantly being overcharged and manipulated. These companies raise prices and abuse their powers since the people had no choice but to use their services. So switching to steel positively transformed the transport sector. Best Steel started making heavy and faster cars and engines due to its greater strength and durability.

This results in the mushrooming of many best manufacturing activities dependent on steel. Due to this reason, it is obvious that iron and steel effectively fuelled the industrial revolution. Europe and Britain in particular, was the heart of this revolution mainly because of their large supply of coal and iron ore.

The growth of the steel industry influenced the development of many other industries. Getting Flexi, strong and versatile TMT bars at a cheaper rate, leading to the rise in industries such as construction, bridges, factories, machine, and buildings.

After 1890, the Bessemer process was gradually superseded by open-hearth steel-making. In the 20th century, this process was further enhanced for the production of high-quality alloy steel. Nowadays TMT Steel has become the most important material for building and infrastructure. Steel is the designer of a wide range of manufacturing activities. It is indispensable in research and development projects around the world.

CONCLUDE

India is currently the world’s 2nd largest producer of Top TMT Bars. India is producing 111.245 million tonnes of crude steel with a growth rate of 1.8% over CPLY. Best Steel is also fully recyclable, which makes it a potential candidate to drive a sustainable present and future.

Top 5 TMT Brand In India

- SAIL

- TATA Tiscon

- JSW

- ESSAR STEEL

- SHYAM STEEL